It happens to most people over time in various levels of severity. Clogged arteries are known as a “hidden disease,” yet it is a major problem that is responsible for one in four deaths each year.

And it’s a lot like oil fouling.

Just as arteries get clogged over time, heating, ventilation and air conditioning units accumulate oil on the compressor from different lubricants. These oil deposits begin to build up over the course of time, thus decreasing the efficiency of your HVAC system.

The good news is there is something you can do about it.

What is oil fouling?

Oil fouling is defined as the accumulation of unwanted oil deposits in the oil system.

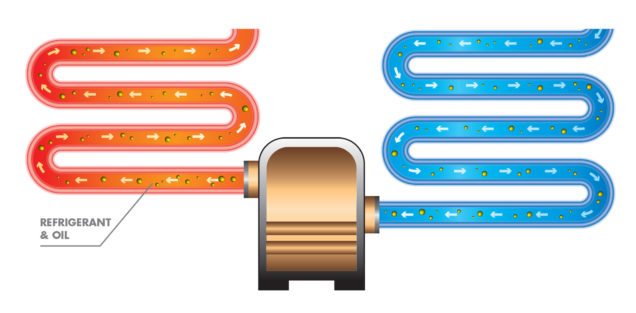

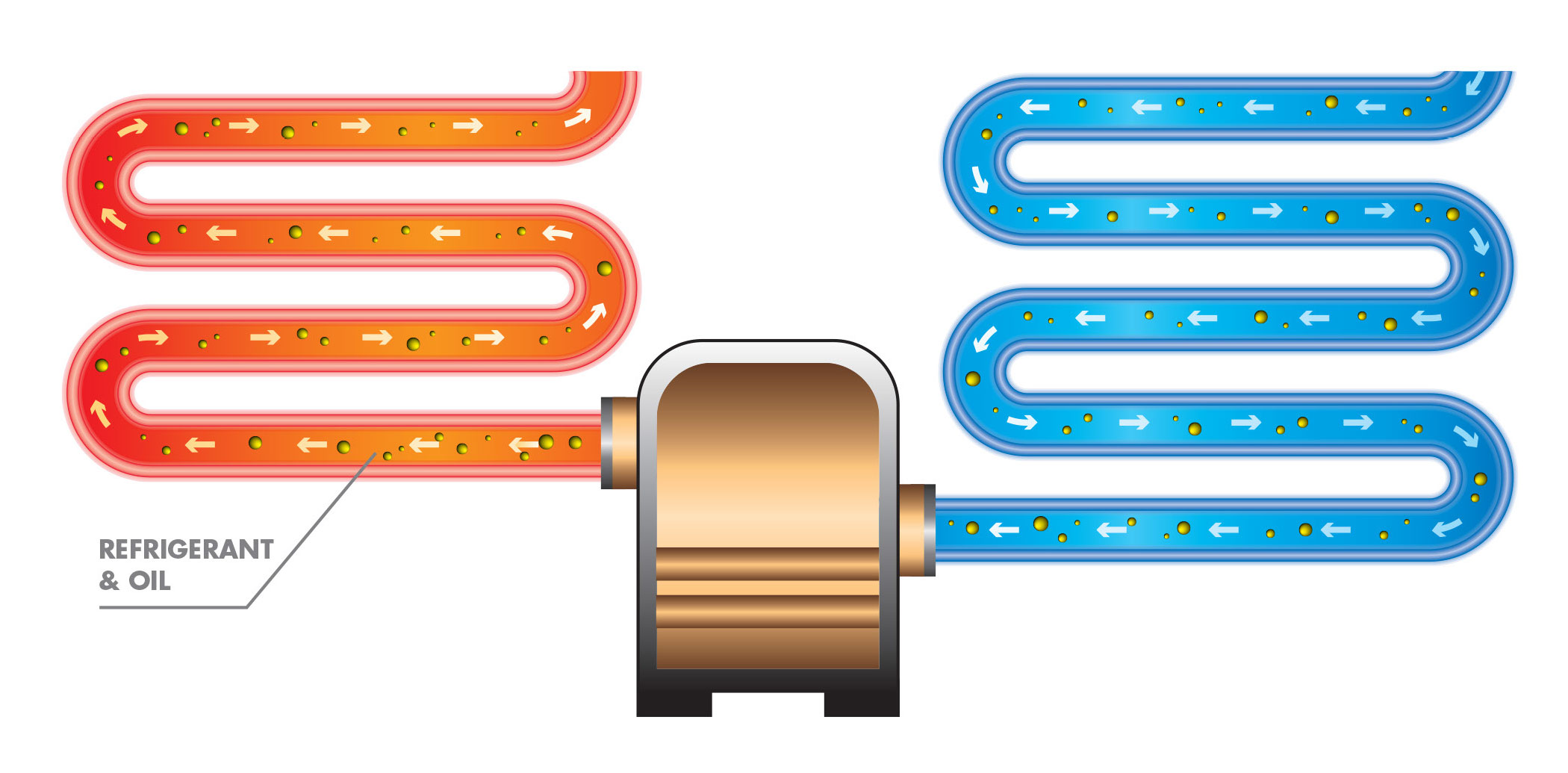

As studied by ASHRAE, during the refrigerant compression process, oil migrates from the compressor to the coil system contaminating

metals that transfer heat.

Compressors that use oil for lubrication do not prevent oil from fouling the coil system. Even the smallest amount of oil in the coil system creates a film or coating that will hinder heat transfer reducing the efficiency of the unit.

Research by ASHRAE shows oil fouling of heat transfer surfaces of air conditioning and refrigeration systems will cause a loss of about 7 percent efficiency in the first year, 5 percent in the second year, and 2 percent per year the following years to a peak degradation of between 20 and 30 percent (1).

How does oil fouling impact air conditioning and refrigeration systems?

Lubricating oil is a necessary evil needed for most mechanical compressors used in air conditioning and refrigeration systems. It’s normal for up to 8 percent of the compressor’s lubricating oil to circulate through the system with the refrigerant, according to information released by the Refrigeration Systems Engineers Society (RSES).

While a small amount of oil in circulation is not harmful, larger amounts the following problems, according to RSES:

- Oil circulating with the refrigerant is not in the compressor crankcase where it should be. As a result, bearings and other parts may not be properly lubricated. Adding more oil after start-up to compensate is not a solution, because the amount of oil circulating with the refrigerant is not consistent throughout the system.

- Excess oil may accumulate in the evaporator and then return to the compressor in a slug. This could overfill the crankcase and possibly damage the compressor.

- Excessive amounts of oil in an evaporator decrease the capacity of a system. If suction pressure controls the compressor, it stops running at a higher temperature when vapor pressure is reduced. If evaporating temperature controls the compressor, then it runs longer to maintain a given temperature when vapor pressure is reduced. Third, oil in the refrigerant may cause restrictions in expansion valves or capillaries, and thus reduce refrigerant flow.

- Circulating oil may break down at hot spots in the system and cause varnishing and valve sticking. It may react with the refrigerant at high temperatures and form acids.

How do you reduce oil fouling?

By using a synthetically enhanced refrigerant additive like Bluemaxx you can reduce oil fouling, improve efficiency and save money on air-cooled and water-cooled systems.

Bluemaxx is a stable, non-corrosive liquid that is added to the refrigerant of a cooling system, helping to reduce A/C energy consumption and increase cooling capacity.

The liquid evaporates refrigerant at a higher temperature, thus taking more heat out of the air, making colder air come out of the supply vents.

It works with all common refrigerants, improving the transfer of heat coils, delivering colder vent air and removing oil fouling.

What are the financial benefits to reducing oil fouling?

In addition to reducing your carbon footprint, using a product like Bluemaxx extends the life of your systems. The life of your compressor should last longer, maintenance costs should be reduced, and cooling costs in general should decrease.

Beyond that, you will live more comfortably in cooler air with less pressure on your systems overall.

Want to learn more about saving money and living more comfortably?

Your compressor is like your arteries and the oil that accumulates is like cholesterol. If you aren’t able to pump blood (cold air) through your arteries (compressor), the system fails (heart attack, no cold air).

Bluemaxx, a synthetic refrigerant additive, helps reduce oil fouling, kind of like a Lipitor for your compressor.

The oil deposit has a stronger affinity to the chemical compounds in Bluemaxx than it does to the metal coils in the compressor. It is then circulated throughout the system, allowing better flow and a cooler feeling system.

Consider using a synthetic refrigerant enhancer to pack a powerful punch that can help your home or business be more comfortable for less money.

Contact us for more information today.

- ASHRAE Handbook, Refrigeration, Chapter 2.9.